With the arrival of spring, the temperature is gradually rising, and industrial air conditioners will usher in a period of frequent use. Doing spring maintenance can make industrial air conditioners run efficiently, extend their service life, and provide a stable environment for enterprise production. The following Jiangsu Jiangsu Jincheng Air Conditioning Engineering Co., Ltd. to share the spring industrial air conditioning maintenance knowledge.

Spring golden period to air conditioning field depth "SPA"

1. Cleaning is crucial

Filter cleaning

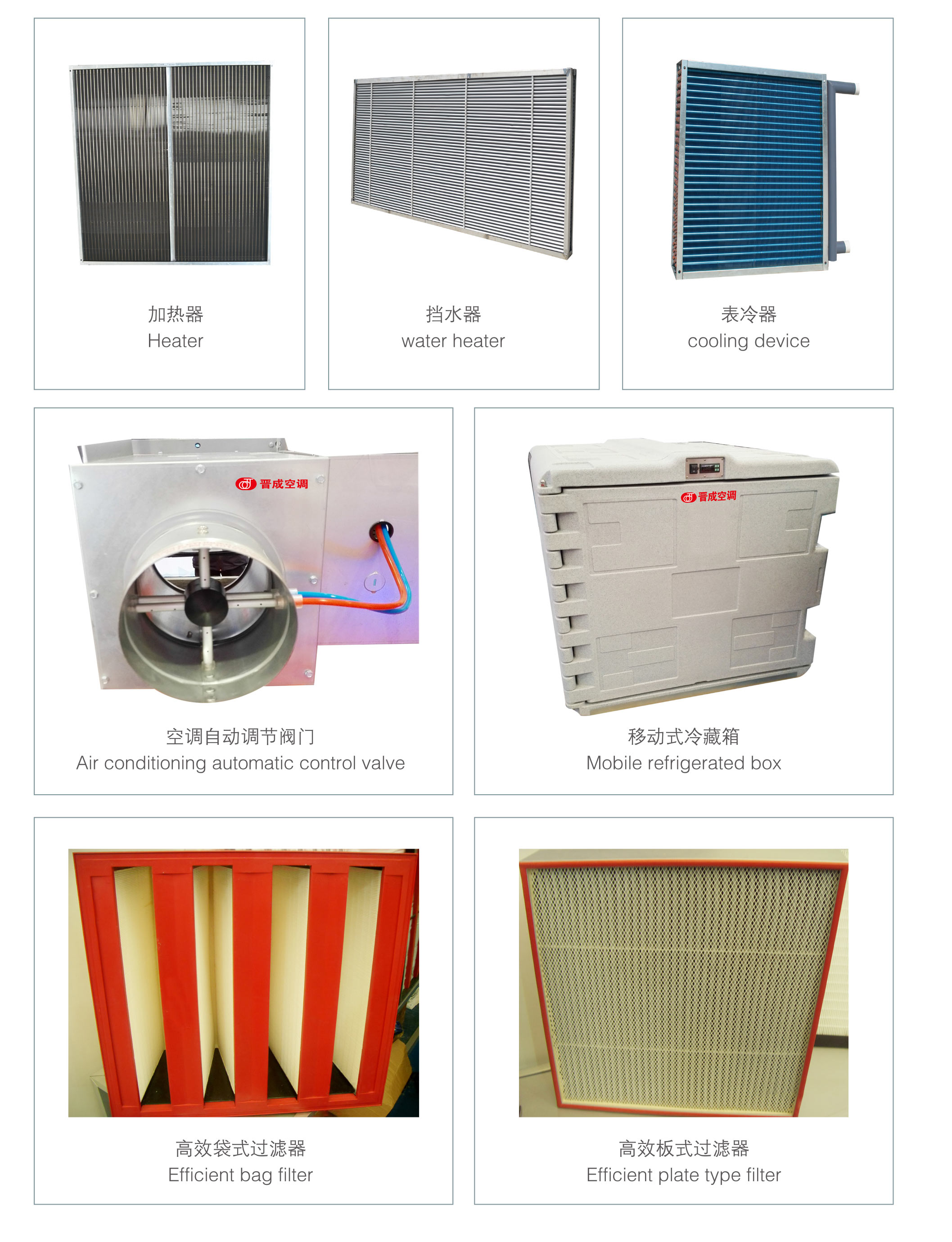

The filter is a key component to prevent dust and dirt from entering the air conditioning. After a long time of use, it will accumulate a lot of dust, resulting in poor air circulation, reducing the cooling or heating effect. It is recommended to clean the filter every 1-2 months. When cleaning, use a vacuum cleaner to remove the surface dust, and then rinse gently with water if the filter allows water to be washed. However, it should be noted that some filters can not be washed, be sure to refer to the product manual operation. After washing, it is necessary to dry naturally in a ventilated place to avoid exposure to sunlight to prevent filter deformation and affect the filtration effect.

Clean condenser and evaporator

Condenser and evaporator are important parts of heat exchange, and their cleanliness directly affects the performance of air conditioning. During spring maintenance, use a soft brush or compressed air to carefully clean the dirt on the surface of the condenser and evaporator. For stubborn dirt, you can choose a professional air conditioner cleaning agent, but you must strictly follow the instructions of the cleaning agent to operate to avoid damage to the equipment. During the cleaning process, be careful not to let water splash on the electrical parts to prevent faults such as short circuit.

External heat sink and body cleaning

Dust and debris are easily attached to the heat sink of the outdoor unit, which affects the heat dissipation efficiency. Use a soft brush or special cleaning agent to gently scrub the surface of the heat sink, and be careful not to rinse directly with water to avoid damage to the circuit. At the same time, wipe the air conditioner shell with a damp cloth to remove dust and stains on the surface and keep the air conditioner clean. The filter is a key component to prevent dust and dirt from entering the air conditioning. After a long time of use, it will accumulate a lot of dust, resulting in poor air circulation, reducing the cooling or heating effect. It is recommended to clean the filter every 1-2 months. When cleaning, use a vacuum cleaner to remove the surface dust, and then rinse gently with water if the filter allows water to be washed. However, it should be noted that some filters can not be washed, be sure to refer to the product manual operation. After washing, it is necessary to dry naturally in a ventilated place to avoid exposure to sunlight to prevent filter deformation and affect the filtration effect.

The condenser and evaporator are clean and cold

Condenser and evaporator are important parts of heat exchange, and their cleanliness directly affects the performance of air conditioning. During spring maintenance, use a soft brush or compressed air to carefully clean the dirt on the surface of the condenser and evaporator. For stubborn dirt, you can choose a professional air conditioner cleaning agent, but you must strictly follow the instructions of the cleaning agent to operate to avoid damage to the equipment. During the cleaning process, be careful not to let water splash on the electrical parts to prevent faults such as short circuit. External heat sink and body cleaning: The heat sink of the outdoor unit is easy to adhere to dust and debris, which will affect the heat dissipation efficiency. Use a soft brush or special cleaning agent to gently scrub the surface of the heat sink, and be careful not to rinse directly with water to avoid damage to the circuit. At the same time, wipe the air conditioner shell with a damp cloth to remove dust and stains on the surface and keep the air conditioner clean.

2, system inspection is indispensable

Refrigerant inspection

Refrigerant is the core medium for air conditioning cooling or heating. Check the pressure and amount of refrigerant regularly to determine whether it is in the normal range. If the refrigerant pressure is too low or too high, it may mean that the system has a leak or improper charge. If any exception is found, contact professional technical personnel to detect, supplement, or maintain the air conditioner to prevent performance deterioration or device damage caused by refrigerant problems.

Electrical connection check

Carefully check the electrical connection parts of the air conditioner, such as power cables and control cables, to ensure that the wires and plugs are not loose, damaged, or aging. Loose wires can cause electrical failures and even pose a fire risk; Damaged or aged wires need to be replaced in time. In addition, it is necessary to check the contactors, relays and other components in the electrical box to see whether the contacts are good, whether there is ablation, oxidation, etc., if there is a problem, it should be repaired or replaced in time.

Drainage system inspection

If the drainage pipe accumulates dirt and is blocked, the water flow is not smooth, and even water leakage occurs, which damages the equipment and affects the production environment. Check drainage pipes regularly, and use pipe dredging tools to clean up internal debris to ensure smooth drainage. At the same time, clean the drainage tray, remove the water and dirt in the tray, and prevent the growth of bacteria and odor.

Control system calibration

The control system of industrial air conditioning plays a key role in the accurate control of temperature, humidity and other parameters. In spring, the control system can be calibrated to ensure that the parameters are set accurately and the temperature and humidity are controlled stably. According to the actual production requirements, the controller Settings are properly adjusted to make the air conditioner better meet the requirements of the working environment.

3, component maintenance points

Lubricating moving parts

The compressor, fan and other moving parts of the air conditioner will wear out due to friction during long-term operation. According to the recommendations of the equipment manufacturer, regularly add an appropriate amount of lubricating oil or grease to these moving parts, which can effectively reduce friction, reduce the degree of wear, extend the service life of the equipment, but also reduce the operating noise, so that the air conditioning can run more smoothly.

Check fan belt

If the industrial air conditioner uses a belt driven fan, check whether the tightness of the fan belt is appropriate. Too loose belt will cause the fan speed to decrease and affect the air supply volume; Too tight will increase the motor load and shorten the service life of the belt and motor. In general, press the middle of the belt with your fingers, and the sinking amount is about 10-15 mm. At the same time, check whether the belt has wear, cracks, etc. If there is an anomaly, the belt should be replaced in time.

Tighten screws and components

Use tools such as a screwdriver to check and tighten all screws on the air conditioner, especially screws on the outdoor unit base, mounting plate, and connecting parts. Ensure that the air conditioner is securely installed to prevent parts from loosening due to vibration during operation, which may cause safety risks.

Spring Industrial air conditioning Maintenance Guide

Appearance and installation check

Clean the shell: wipe off the dust and stains of the air conditioner shell with a damp cloth, and use a mild cleaning agent on the stubborn parts. Do not let the cleaning agent enter.

Check the installation parts: Check the supports and screws. If they are loose, deformed, or rusty, tighten, replace, or take anti-rust treatment in time to ensure stable installation. Clean up the surrounding environment: Remove obstacles such as weeds and leaves around the outdoor unit, and maintain a 0.5-1 meter space to ensure air circulation.

Deep internal cleaning

Clean the filter: remove the filter regularly, rinse with clean water or brush lightly with a soft brush, soak in neutral detergent when dirty, wash and dry before putting back.

Clean the heat exchanger: the evaporator and condenser are sprayed with professional detergent, then washed with water or vacuum cleaner to remove dirt, can use high pressure water gun but pay attention to waterproof into the electrical parts. Dredge the drainage system: check whether the drainage pipe is blocked or leaking, clean the debris with tools, clean the drainage tray, and prevent water from breeding bacteria.

Electrical system maintenance

Check cable connections: Check power cables and control cables, tighten loose parts, and replace damaged or aging cables in time to prevent electrical faults.

Test electrical components: Use a multimeter to measure the performance of compressors, fans and other components, check the insulation resistance, and replace the components when they are damaged. Clean the electrical box: clean the dust and debris in the electrical box, check the contacts such as contactors, and repair or replace them in time if there is ablation or oxidation.

Refrigerant system inspection

Test the refrigerant pressure: use professional tools to measure the system pressure, check whether it is normal according to the instruction manual, and check whether the leakage or charge amount is abnormal. Check refrigerant leakage: Check pipelines, joints, valves and other parts for oil stains, bubbles, leakage in time to repair and replenish refrigerant. Check the filter dryer: Determine whether it is blocked by pressure difference or temperature change, and replace it if it is blocked.